Earth Club enlists students to design water bottle filler

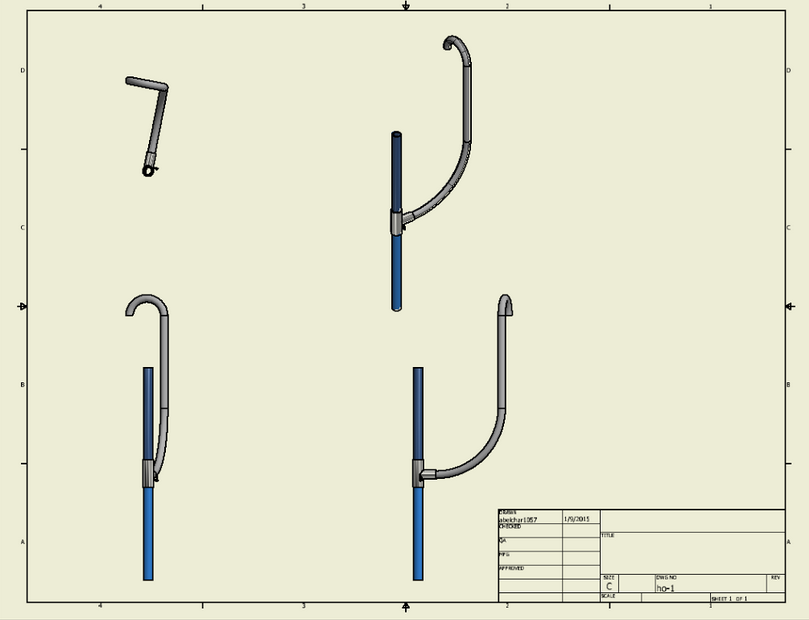

Blueprint of the water bottle filler add-on designed by Zach Shear, Andrew Patel, and Charlie Abel, juniors.

Feb 25, 2015

What started as class curriculum turned into a commissioned project for Mechanical Engineering students Zach Shear, Andrew Patel, and Charlie Abel, juniors.

Earth Club wanted more water bottle filling stations at HHS, but hiring a professional to do the job would cost thousands of dollars. After failing to acquire a grant, the club found a cheaper solution in the Technology Department.

Mechanical Engineering students normally have a final project to undertake at the end of the semester, but Mr. Rob Fuhr, Technology Department and Earth Club advisor, assigned the task of designing a new, cost-efficient filler option to Shear, Patel, and Abel specifically.

“I had [Shear, Patel, and Abel] as sophomores in Introduction to Engineering, so as advanced students, I tried to get more of a practical application for what they’ve learned,” Fuhr said. “I tried to get them a real world problem-solving assignment.”

So, the boys took on the challenge to solve a real scenario affecting their community – a real engineering experience.

“We started off just brainstorming ideas – how to make it work. We drew up all the parts we were going to need on Autodesk Inventor, a 3D modeling program,” Shear said.

Shear, Patel, and Abel designed their water bottle filler from scratch, but to figure out the mechanics of the water fountain system, they had to do some research.

“We took apart one of the water fountains in the school – in the Tech Ed hallway by the wood shop – in the middle of class to see how the fillers that are already being made work, and based off that, we came up with our own idea that we thought would be simpler and cheaper,” Shear said. “We were right.”

The filler add-on they designed resembles a sink faucet coming out of a normal drinking fountain. A switch controls the valves within the fountain to determine whether pressing the button will send water through the regular drinking fountain spout or the water bottle filler.

After finalizing their design at the end of the semester-long class, Shear, Patel, and Abel, accompanied by members of Earth Club, presented their idea to the administration. The boys were shocked when they were then asked to build a prototype.

“Fuhr said [the administration] would most likely say no because of health concerns – like students wouldn’t be able to install all the piping and stuff,” Patel said. “So, we were pretty surprised [when they said yes].”

Shear, Patel, and Abel will start constructing the prototype as soon as the parts arrive. If the administration approves it, their filler could become a permanent part of HHS.

However, getting their design to that point will require much more work.

“There are still questions as to whether it will be sturdy enough, so that’s a technical issue that we have to look at,” Fuhr said. “That’s kind of the process of engineering – to design, test, and build a prototype and then to redesign, retest, and build again. We’re in that first step.”

All three of the boys want to pursue engineering after high school, so they appreciate the experience this project gave them.

“[The project] will look good on a college application or resume,” Patel said.

Yet, with all of the hours they’ve invested into the filler, they are excited to be done with it once and for all.

“We’ve spent so much time looking at it,” Shear said. “But we designed it, so we want to finish it.”